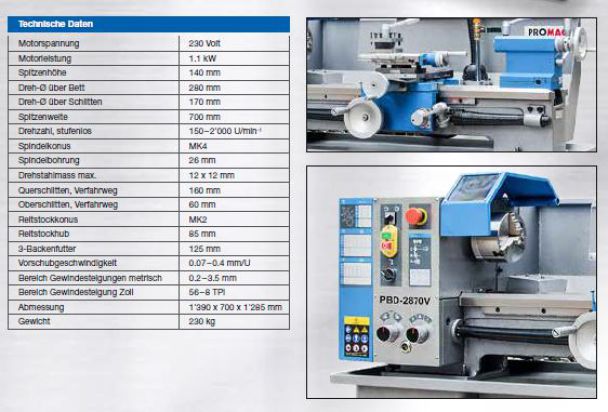

PROMAC PBD-2870 Metalldrehmaschine

Bilddaten:

Tagged Image File [74.4 MB]

JPG-Datei [529.6 KB]

JPG-Datei [802.7 KB]

Bilddaten:

JPG-Datei [55.5 KB]

JPG-Datei [51.3 KB]

JPG-Datei [34.2 KB]

JPG-Datei [27.1 KB]

JPG-Datei [22.4 KB]

JPG-Datei [62.3 KB]

JPG-Datei [44.6 KB]

JPG-Datei [43.5 KB]

JPG-Datei [38.8 KB]

JPG-Datei [25.1 KB]

JPG-Datei [30.8 KB]

JPG-Datei [32.8 KB]

JPG-Datei [36.5 KB]

JPG-Datei [30.1 KB]

JPG-Datei [36.8 KB]

- Automatischer Längsvorschub

- Stufenlose, elektronische Drehzahlregulierung

- Integriertes Kühlmittelsystem

- Integrierte Maschinenleuchte

- Inkl. Maschinensockel

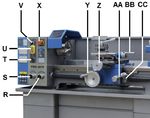

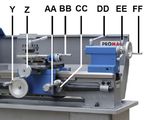

Figure 5‐1: Machine description

A ............................................ Machine cabinet stand

B .................................................................. Gear box

C ..............................................................Pulley cover

D ............................................................... Headstock

E ............................................ Chuck and chuck guard

F .................................. Tool post and tool post guard

G ......................................................... Machine lamp

H ........................................................ Coolant nozzle

I .................................................................... Top slide

J ..................................................................... Carriage

K ................................................................... Tailstock

L ............................................................ Splash guard

M ............................................................... Lathe bed

N .............................................................. Lead screw

O .................................................................. Chip tray

P ....................................................................... Apron

Q .................................................... Anchor bolt holes

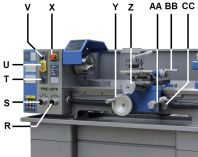

Figure 5‐2: Machine description

R ........................................... Feed speed select knob

S ........................................ Feed forward/off/reverse

T ...................................................... Coolant ON/OFF

U ............................................ Spindle power ON/OFF

V ......................................... Spindle forward/reverse

X .......................................................Emergency Stop

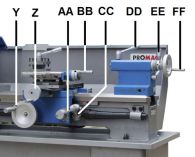

Y ................................................... Apron hand wheel

Z ............................................ Cross slide hand wheel

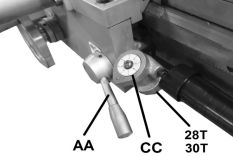

AA ......................................................... Half nut lever

BB ............................................ Top slide hand wheel

CC ........................................................ Threading dial

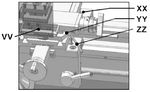

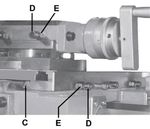

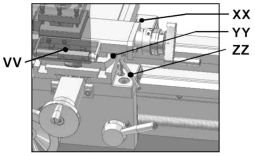

Figure 5‐3 Machine description

VV ......................................................... Top slide lock

XX ...................................................... Cross slide lock

YY ................................... Top slide taper adjustment

ZZ ........................................................... Carriage lock

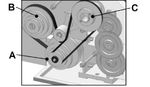

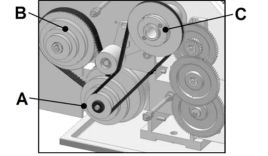

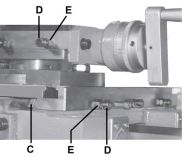

Figure 8‐2: Change gear setup

Remove the pulley cover.

The rotational speed of the lead screw, and hence the rate of

feed of the cutting tool, is determined by the gear

configuration and by the feed speed select lever (R, Fig 5‐2).

Assemble the gears with desired setup (Fig 8‐2)

Adjust gears to mesh with upper and lower gear.

Placing ordinary paper in between gears helps to adjust for

correct gear spacing (… remove the paper afterwards!).

Reinstall the pulley cover

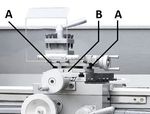

Refer to Figure 9‐1:

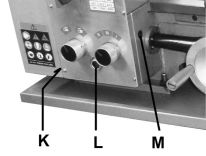

R ............................................. Feed select knob

S ............................... Feed forward/off/reverse

T .............................................. Coolant ON/OFF

U .................................. Spindle power ON/OFF

V ................................. Spindle forward/reverse

X .............................................. Emergency Stop

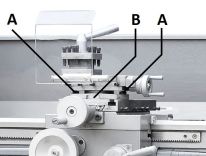

Figure 10‐6: Machine controls

Apron travel (Y, Fig 10‐6), cross travel (Z) and top slide travel

(BB) can be operated for longitudinal and cross feeding

The correct feed depends on the material to be cut, the cutting

operation, the type of tool, the rigidity of the work piece

chucking, the depth of cut and the desired surface quality.

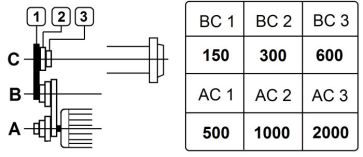

Figure 10‐7: Available feed rates

For example:

Operation feed/rev feed select knob

Stock removal 0,28mm .............................. III

Finishing cut 0.14mm ............................... II

Micro finishing cut 0.07mm ................................ I

NOTE: Three additional feed rates are available with different

change gear setup (Fig 10‐7).

Optionales Zubehör / optional accessories:

PDF-Dokument [1.9 MB]

Bedienungsanleitung / Manual:

Ersatzteilliste / Part List:

PDF-Dokument [6.1 MB]

PDF-Dokument [4.5 MB]

Sollten Sie weitere Fragen haben, zögern Sie nicht uns zu kontaktieren.

Should you have any further questions, please do not hesitate to contact us.